A major Oil and Gas Terminal in the Mid-Atlantic called on Geiger Pump to investigate frequent seal failures on a demanding lube oil service, with some instances occurring less than 3 months after start-up. Upon inspection, the cause of failure was likely the blistering on the carbon primary ring inside the seal. The recommended solution was to switch to a diamond coated mating ring. The initial diamond face mechanical seal was installed more than one year ago with no failures to date. Since then, an additional 6 diamond coated seals have been purchased and installed on similar pumps.

The Problem: Frequent Seal Failures

The Customer was experiencing frequent seal failures on gear pumps processing lube oil service, with a high proportion of gas in the fluid, and a max temperature of 180oF.

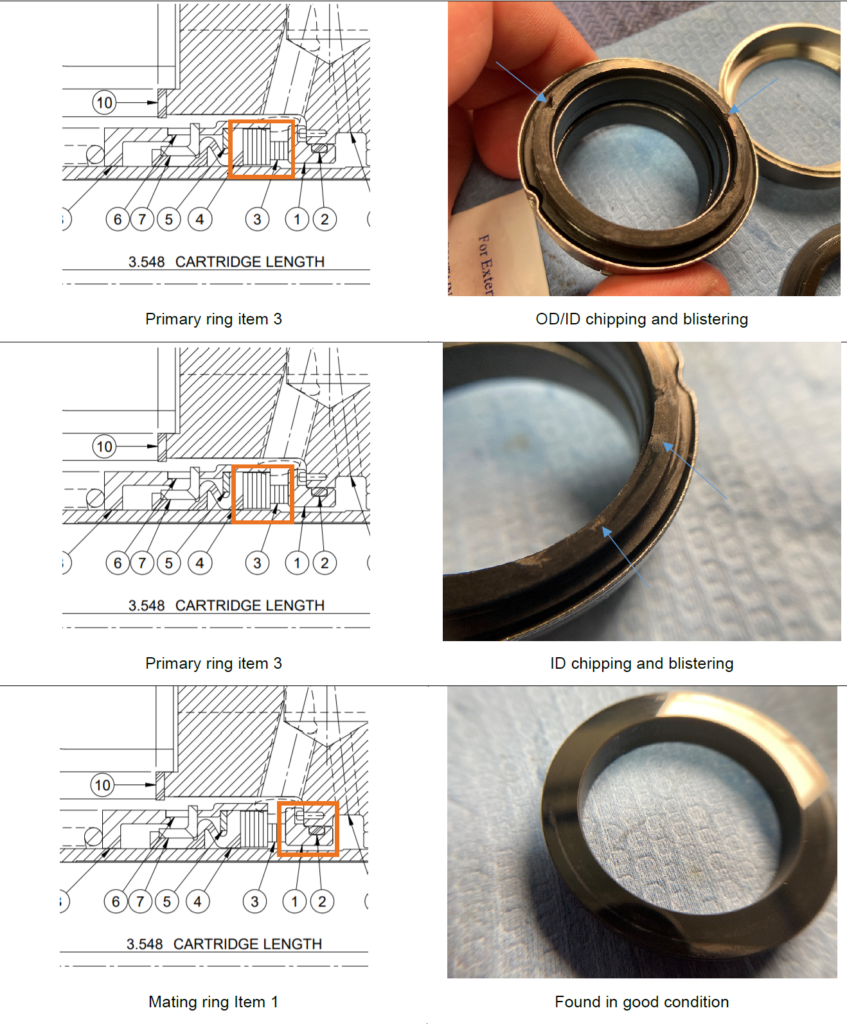

Inspection uncovered the following evidence:

- Varnish on the atmospheric side of the seal

- Scattered solid particles in the oil inside the seal

- Chips on the ID and OD of the primary ring

- Non-chipped areas presented extensive blistering

- Blisters of various stages on the primary ring face of the seal

Blistering of the seal face is commonly associated with carbon seal faces operating on liquids of high viscosity, and/or rapid starting and stopping.

Due to the high percentage of gas in the fluid, periods of dry run were suspected of contributing to the failure, together with the solid particles observed in the fluid.

The Solution: Diamond Face Mechanical Seals

The most severe failure was the blistering on the carbon primary ring. Common solutions to reduce blistering include:

- Changing to a low viscosity oil

- Warming up the oil

- Reducing the number of starts or

- Changing to a hard face seal

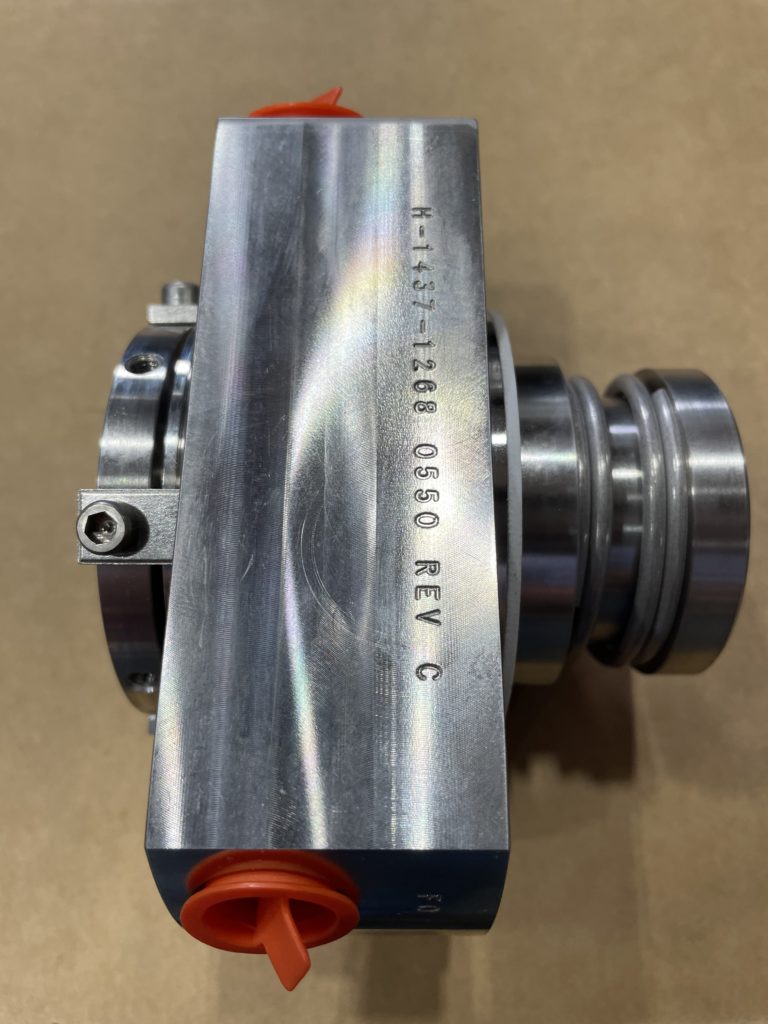

For this particular situation, switching to the John Crane Diamond Seal Face Technology was determined to be the best solution.

This particular service has entrained gas and high temperature liquid. Diamond face mechanical seals offer a low coefficient of friction and will generate less heat allowing the seal to run cooler, even in times of dry run. Diamond seal face coating is a proven solution for abrasive fluids, fluids with low lubricity, and intermittent dry running; conditions similar to those faced by the customer.

The Results: 300% Life Extension

The Customer chose to replace the seal that failed after 3 months of operation with a diamond faced seal. The diamond face seal has been operational for more than a year now without failure, a 300% life extension.

Due to the success of the diamond faced seal in this environment, the customer replaced an additional six seals with diamond faced seals on similar service pumps.

For more information on choosing the right seal for your environment or help determining if a diamond face seal is right for you, contact our engineering team.