Chemical Metering

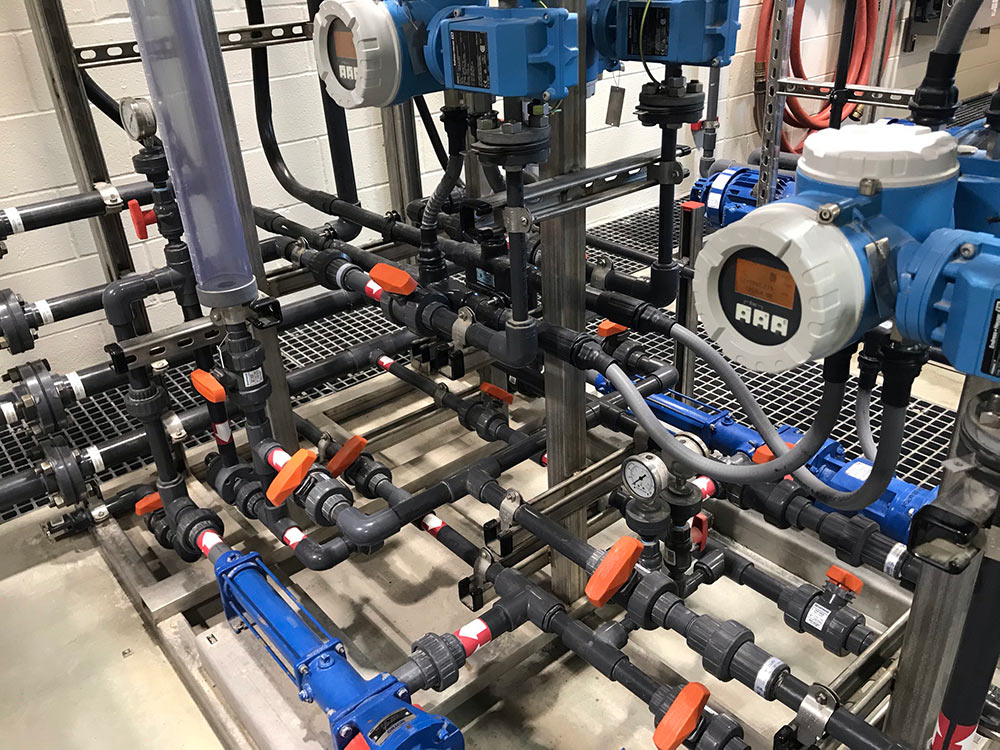

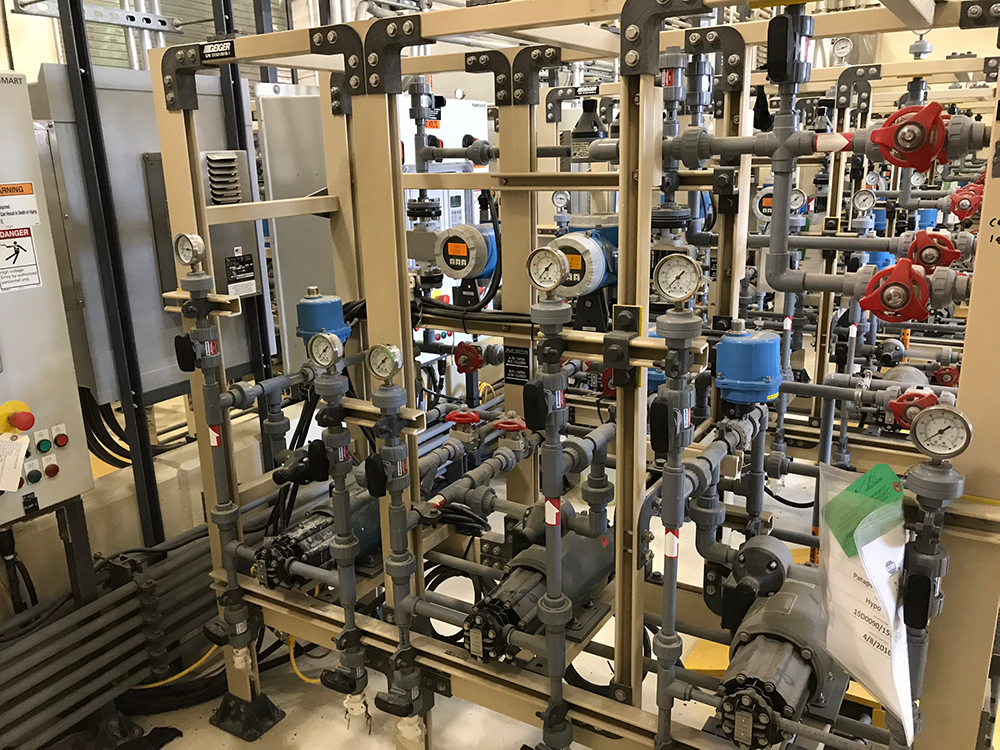

Geiger’s Metering Systems are used in both municipal and industrial settings with a wide variety of chemicals, including Sodium Hypochlorite, Sodium Hydroxide (caustic), Polymer, Methanol, Ethanol, Ferric Chloride, dyes, additives, and more. Common applications include disinfection, pH/ORP control, batching, Enhanced Nutrient Removal (ENR), dilution and blending, biocide, additive injection, and beyond.

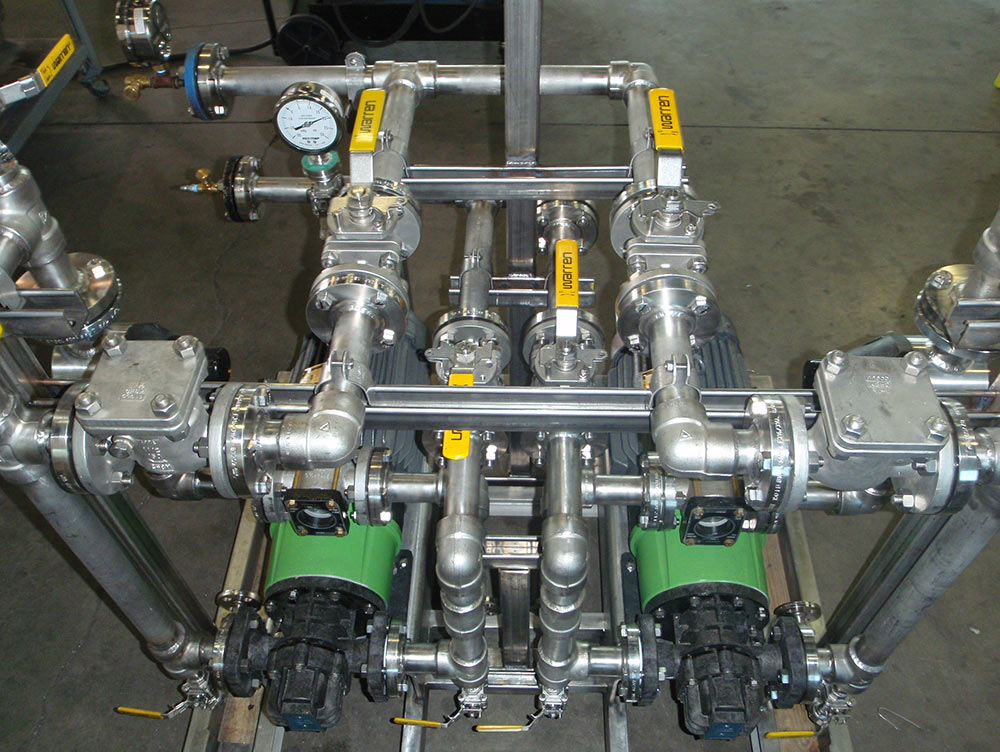

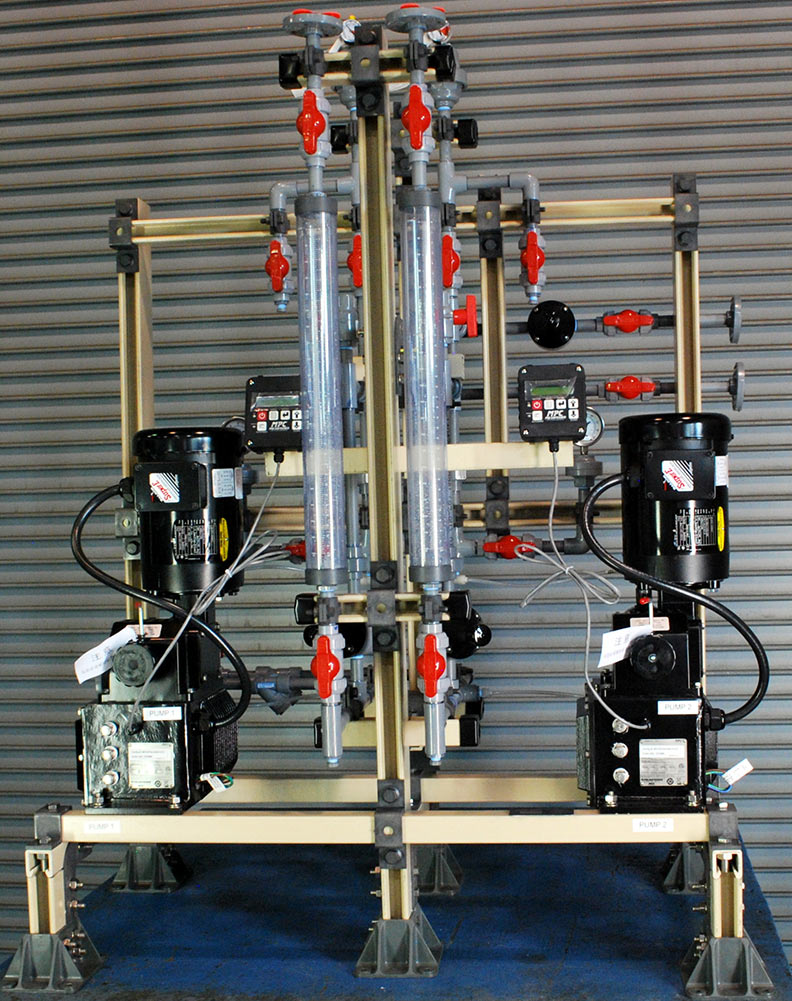

Our expert team starts by selecting the optimal pump for the application. From there we design a coordinated, integrated metering system including all the components needed for a functional, reliable system including pumps, controls, instruments, valves, control valves, pipe and fittings, and other accessories coordinated with the pump and application.

Our team takes special care to assure ensure systems are designed so all components are accessible to the operator and maintenance personnel, fast to install by the contractor, and easy to specify and review as a complete unit.

Geiger Offers:

Seal-less Gear Pump Metering Systems: Magnetically driven, seal-less gear pumps that can be rebuilt with a kit in 5 minutes flat are the center of these widely used systems. Available in metallic and non-metallic construction, our metering systems include everything you need for a complete, functional system right out of the crate.

Diaphragm Pump Metering Systems: No-lost motion, hydraulically driven diaphragm metering pumps provide the highest level of accuracy. Geiger designs our systems with pulsation dampers, controls, back pressure valves, and all the components needed to make an easily maintained, reliable system.

Progressing Cavity Metering Systems: Progressing cavity metering pumps offer high accuracy, low pulsation metering of high viscosity and/or shear sensitive fluids. Geiger uses PC pumps for polymer blending and aging systems, oil-water separator systems, and applications where high turndown is needed while maintaining higher pressures and smooth flow. Our metering systems’ integrated controls can be designed to monitor pump performance and protect progressing cavity pump systems against high pressures.

Peristaltic Pump Metering Systems: Hose and Tube pumps offer easy maintenance, broad chemical compatibility, and the ability to handle abrasive fluids. Peristaltic metering pump systems include pulsation dampers, calibration columns, isolation valves, gauges, controls, and more, and are designed to assure ensure easy regular maintenance.

Gear Pump Metering Systems: Internal and External Gear pumps can be used for metering, especially in high pressure injection or batching systems. Economical and reliable, these systems are offered either fully assembled, or in kits with accessories for specific applications such as batching.

Custom Solutions: Geiger can work with your team to design chemical metering systems to fit your application and assure ensure coordination throughout the system. We can include chemical storage tanks, weather and sound enclosures, dilution systems, truck offloading stations, drum and tote unloading systems, injection quills, instrumentation such as densitometers, pH probes, mass flow meters, and coordinating controls, and more. Our engineering team will work with you to understand the requirements of your process and installation and will design a chemical metering solution to meet your needs.

Product Lines Available:

- Pulsafeeder

- Verder

- Viking

- Moyno

- Engineered Systems by Geiger

- And more – our applications team can assist

Chemical Metering

Contact us to discuss your application