Monitoring & Controls

Geiger’s control and monitoring solutions focus on pumps, blowers, vacuum pumps, and fans. From Variable Frequency Drives (VFDs) optimized for pump control, control panels for common applications, custom solutions tailored to a particular application, sensors with automated analytics for simplified vibration monitoring, Geiger’s control products are made to make equipment easier to integrate and more reliable.

Geiger Offers:

- Variable Frequency Drives: Geiger offers drives designed to optimize and simplify pump operation. Features include dry run and run out control, integrated process variable and multi-pump control, and sensorless flow control, which allow us to coordinate the right drive for your application with your pump or other equipment.

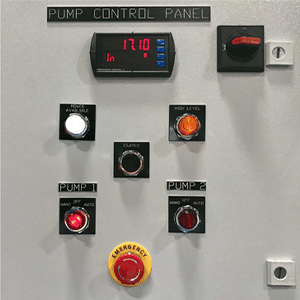

- Standard Control Panels: Duplex control panels including motor starters, overloads, main disconnect, run lights, switches, alarming, and lead/lag and automatic alternation functions.

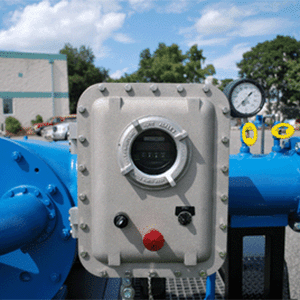

- Process Control Panels: Control a single or multi-pump process variable, such as level, pressure, or flow, with variable speed drives or constant speed motor starters and a controller. These panels are configurable and can also be used for monitoring.

- Custom Control Panels: Custom control panels to meet the requirements of your particular pump or vacuum/blower system. We offer coordination, specification and design assistance, and functional testing with your other equipment in the factory before shipment.

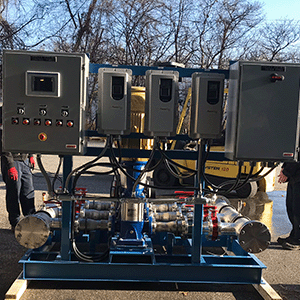

- Integrated Systems and Kits: We take the legwork out of coordination with skids and kits with integrated controls for applications including pressure boosting, batch control, level control, multi-pump control, Air-Operated Diaphragm (AOD) pump control, dilution and blending systems, truck loading and unloading, and more.

Products

PumpSmart 220

Aquavar IPC

Process Control Panels

VFD Control Panels

Duplex Control Panels

Operator’s Stations

Custom Solutions

Contact us to determine the best monitoring and control solution for your application

Monitoring & Controls Repair Services

Our service and repair group can use data collected by various monitoring technologies, getting to the root of vibration or noise issues, nuisance alarms and faults, and more.

Contact us for more information on our service and repair capabilities.

Frequently Asked Questions

After turning off power and letting the capacitors discharge, swap any two leads to the motor. Some drives can also change rotation with programming; this should be done with caution as many impellers are threaded on! Note, because the VFD is controlling the frequency output to the motor, changing the incoming feeds will NOT change the rotation.

Variable Speed Drives take incoming line alternating current (AC) power and change it to direct current (DC) power, and then use high speed switches to simulate alternating current output to the drive, which allows control of the frequency of the power going to the drive. Even when the incoming power is single phase because the drives are rectifying the power to DC, They are designed to output three phase power because three phase motors are more efficient and use lower current.

It comes down to your pump sizing and details of your use and application. For example, if you are constantly throttling a centrifugal pump with a control valve, A variable speed drive can save energy making for a quick payback time. Alternately, if your pump is ideally sized for your service and runs at the best efficiency point (BEP) regularly, you may not benefit from variable speed control (unless you need a soft start, dry run, or run out protection). Please contact us to discuss your needs.

Often, no! Modern VFDs can perform many functions, like process variable control or multi-pump coordination, without an additional PLC. However, some applications are enough “out of the box” that an additional controller is needed. Please contact us to discuss your equipment.

Why Geiger?

Geiger has extensive experience integrating rotating equipment into fully functional systems. We know that understanding how the machine works, and also what can cause failure, are critical to selecting and designing control systems that maximize reliability, meet the needs of the user and equipment, and aren’t needlessly complex. Our team is ready to discuss your controls, monitoring, and coordination needs.