When liquids flowing through piping systems suddenly stop or change direction, the resulting shockwave can cause serious damage to equipment and interrupt production. This phenomenon—known as water hammer—is one of the most frequent yet misunderstood challenges in industrial, sanitary, and municipal applications.

At Geiger Pump and Equipment, we’ve partnered with facilities across many industries to identify, diagnose, and eliminate water hammer events that threaten system reliability and operational safety. Understanding the mechanics behind water hammer and implementing proper design strategies can dramatically improve equipment longevity and reduce costly failures.

What Causes Water Hammer?

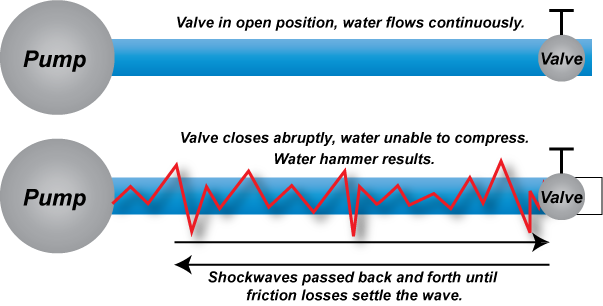

Water hammer occurs when moving fluid experiences a sudden velocity change. Common triggers include rapid valve closure, pump shutdown, or abrupt flow reversal. The kinetic energy of the moving liquid converts instantaneously into pressure, generating a shockwave that propagates through the piping at speeds of thousands of feet per second.

This pressure surge can reach levels ten times higher than normal operating pressure, far exceeding design limits. The resulting damage manifests as loud banging sounds, severe vibration, gasket failures, cracked fittings, damaged valves, and in extreme cases, ruptured pipes. The pressure wave reflects throughout the system until the energy gradually dissipates.

The Momentum Equation: Understanding the Forces

Consider a practical example: a 100-foot section of 4-inch Schedule 40 steel pipe contains roughly 544 pounds of water. If that water flows at 600 feet per minute and stops suddenly, the impact generates approximately 566 foot-pounds of force.

Scale this to larger infrastructure: a 275-foot run of 12-inch stainless pipe holds about 13,478 pounds of water. At 800 feet per minute, an abrupt stop creates 18,325 foot-pounds of force—sufficient to clear production areas. This force doesn’t dissipate immediately; it reverses and rebounds, amplifying stress throughout the system and generating multiple successive hammer events.

Effective water hammer mitigation requires managing both forward momentum (during normal flow) and reverse momentum (during flow reversal).

Why Water Hammer Demands Attention

Financial Impact

Even moderate water hammer events accumulate substantial costs over time. Repeated stress accelerates deterioration of critical components including gaskets, pipe hangers, valves, instrumentation, pumps, mechanical seals, heat exchangers, and pressure vessels. Severe incidents trigger immediate mechanical failures requiring expensive repairs, system shutdowns, and extensive cleanup operations.

Safety Concerns

Beyond equipment damage, intense water hammer events create serious safety hazards. The sudden force can necessitate facility evacuations or cause catastrophic failures in high-pressure lines. These incidents result from fundamental physics in poorly controlled systems—they’re preventable, not inevitable accidents.

Water hammer affects all fluids equally: chemicals, fuels, waste products, and high-temperature liquids all exhibit the same destructive behavior when momentum changes abruptly.

Real-World Case: Eliminating Chronic Failures in Food Processing

A growing food and beverage manufacturer experienced persistent equipment failures across chilled water and clean-in-place (CIP) systems. Operations staff documented sharp banging noises, excessive vibration, and frequent damage to valves, gaskets, and instruments. Production stopped repeatedly for component replacement, generating expensive downtime and product loss risk.

A comprehensive system evaluation determined multiple water hammer sources. Analysis revealed several contributing factors creating destructive pressure transients:

- Fast-closing pneumatic valves stopping flow abruptly

- Slow-closing swing check valves allowing reverse-momentum buildup

- Pump shutdown sequences creating rapid velocity changes

- Inadequate pipe support unable to absorb shock loads

These transient events exceeded mechanical design limits, directly causing the recurring failures.

Engineered Solution Strategy

An integrated mitigation approach was developed to address both forward and reverse momentum while strengthening mechanical infrastructure.

Forward-Momentum Control

- Adjusted pneumatic valve actuation speeds using needle valves for precise timing

- Specified electric actuators with built-in deceleration and pause features

- Optimized valve cycle times to allow gradual closure

Reverse-Momentum Protection

- Replaced slow-closing swing checks with spring-assisted fast-closing check valves

- Modified pump start/stop sequences to minimize hydraulic shock

- Selected check valves with minimal disc travel for rapid seating

Infrastructure Reinforcement

- Upgraded pipe supports in high-vibration zones

- Integrated surge-reducing elements into redesigned process skids

- Corrected sanitary valve flow orientation to reduce turbulence

Results

Implementation of these solutions delivered:

- Substantial reduction in maintenance expenses and component replacement

- Elimination of production interruptions from water hammer events

- Extended equipment service life across pumps, valves, and instrumentation

- Improved facility safety by removing high-energy shock hazards

Management calculated significant annual savings from avoided downtime and premature failures.

Valve Design Principles for Water Hammer Prevention

Managing Forward Momentum: Decelerate Gradually

When controlling forward flow, any closure device must operate carefully. Valves closing too rapidly trap moving liquid with nowhere to dissipate energy, causing instantaneous pressure rise.

- Pneumatic Actuation: Use needle valves to fine-tune closing speed and extend cycle times for gradual closure.

- Valve Orientation: Install sanitary valves correctly relative to flow direction to minimize turbulence and pressure buildup.

- Electric Actuation: Leverage inherently slower electric actuators with cycle times from 10 seconds to several minutes. Advanced models incorporate pause features that temporarily interrupt travel, giving fluid time to decelerate safely.

For forward momentum control, slower actuation is safer.

Managing Reverse Momentum: Close Quickly

During flow reversal following pump shutdown, momentum reverses direction. If check valves close too slowly, reversing fluid accelerates and slams the valve shut with destructive force—one of the most common water hammer sources.

Prevention strategies:

- Select check valves with minimal disc travel distance for faster closure. The Val-Matic Surgebuster uses their patented Disc Accelerator™ to achieve rapid, non-slam closure when flow reverses.

- Avoid swing check valves in critical applications due to their long travel distances

- Specify spring-assisted designs that accelerate closure before reverse flow builds momentum

For reverse momentum protection, rapid closure is essential.

Specific Products to Prevent Water Hammer

There are a number of design practices that when applied to valves can reduce the potential for water hammer but what happens when water hammer is inevitable? Pump starts, stops and power failures can occur at any moment and all can, unfortunately, result in water hammer. In these cases, ensuring you have the smartest products in place can help prevent system damage.

- Variable Speed Drives (such as Vidar): Offer precise speed and torque control that, while ramping a pump up or down, prevents sudden starts or stops.

- Surge Anticipation Valves (such as Singer): Use systems to sense an impending surge and quickly opens the valve to relieve excess pressure before the surge begins and closes after to maintain system integrity.

- Surge Control Vessels (such as Blacoh): Use compressed air or nitrogen within a bladder-like vessel to cushion pressure spikes and then release energy during low-pressure moments.

Special Considerations: Steam Systems

Steam systems present unique water hammer challenges. When steam condenses, water pockets (condensate slugs) form in piping. High-velocity steam—reaching 15,000 feet per minute in superheated systems—accelerates these slugs, creating catastrophic hammer events.

Example: In a 6-inch steam header 300 feet long, a five-gallon condensate slug accelerated by 10,000 feet-per-minute steam generates nearly 700 foot-pounds of force.

Prevention Measures:

- Install drip legs approximately every 300 feet

- Size condensate legs at full pipe diameter up to 4 inches; half diameter above 4 inches

- Maintain steam traps to continuously remove condensate before accumulation

- Use dedicated pumps or pump traps for condensate evacuation rather than relying on steam pressure

- Design heat exchangers to prevent steam/condensate mixing that causes stall conditions

How Geiger Pump & Equipment Can Help

Water hammer can deteriorate equipment for months before symptoms become critical. If you’re experiencing unexplained vibration, repeated valve failures, or system shutdowns, water hammer may be the underlying cause.

Our engineering and field service teams provide:

- System-wide analysis to identify water hammer sources

- Optimized valve actuation solutions and timing strategies

- Custom-engineered process skids with integrated surge control

- Steam system evaluation for proper condensate management

- On-site consultation and implementation support

Whether you operate municipal treatment facilities, industrial process lines, or utility plants, Geiger Pump & Equipment delivers the expertise and equipment to maintain safe, reliable, efficient operations.

Ready to protect your facility? Contact Geiger Pump & Equipment to schedule a comprehensive system evaluation with our process experts.