When it comes to pump maintenance and repair, industrial professionals are constantly seeking solutions that balance cost-effectiveness with long-term reliability. One such solution that has proven its worth in the field is Belzona 1341 Supermetalglide, a specialized coating that’s transforming how we approach pumps, pipes, valves and other fluid handling equipment restoration and protection.

The Challenge: Balancing Economics and Performance

In today’s industrial landscape, maintenance teams face a common dilemma: should they invest in expensive metallurgy upgrades or find more economical way to extend equipment life? This question recently sparked an interesting discussion among maintenance professionals, highlighting the practical considerations that drive real-world decisions.

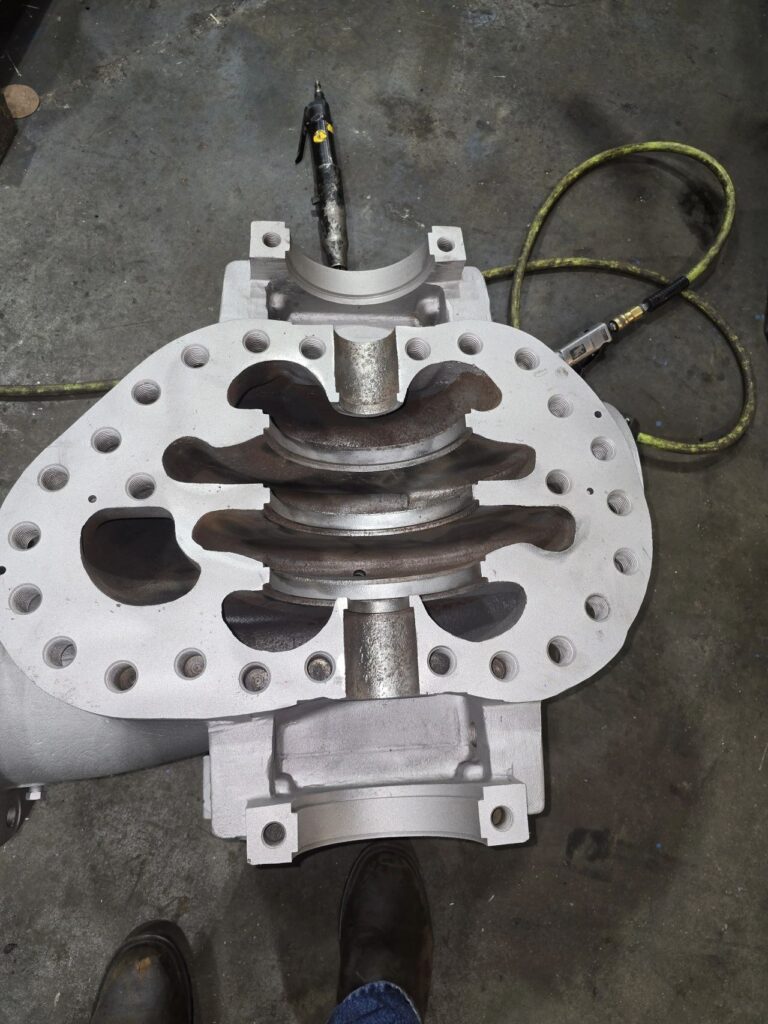

One of Geiger’s experienced millwrights, Josh Burroughs, recently noted when discussing a recent impeller coating project, “It’s significantly more economical to coat this vs replacing given it’s a repair.” This sentiment reflects a broader trend in industrial maintenance where smart material solutions are being used to maximize existing equipment performance rather than defaulting to costly replacements.

The reality of modern maintenance extends beyond simple cost comparisons. With extended lead times becoming increasingly common for replacement parts, repair solutions that can restore and enhance equipment performance provide critical operational value. Josh noted a similar sentiment when discussing a comprehensive pump restoration, “This approach not only restores the casing but also improves efficiency and prevents premature failure—all while avoiding the long lead times and high costs of sourcing a replacement.”

Understanding Belzona 1341 Supermetalglide

Belzona 1341 Supermetalglide stands out in the world of industrial coatings due to its unique properties that make it particularly well-suited for pump applications. The material is hydrophobic and cures to create an exceptionally smooth finish that offers several key advantages:

Superior Wear Resistance: The coating consistently outperforms raw bronze or cast iron in wear applications, extending the operational life of treated components significantly.

Chemical Compatibility: Belzona 1341 demonstrates excellent resistance across a wide range of chemicals, making it suitable for diverse industrial applications where pumps handle various process fluids.

Potable Water Applications: For water treatment and distribution systems, Belzona 1341 offers the additional advantage of being certified for contact with drinking water. The coating meets NSF/ANSI Standard 61 requirements and satisfies UK Drinking Water Inspectorate standards, making it suitable for municipal water systems, food processing applications, and other scenarios where potable water contact is a concern.

Friction Reduction: The smooth, hydrophobic surface reduces friction between the impeller and the fluid being pumped, which can lead to improved pump efficiency and reduced energy consumption.

The Application Process: Precision, Timing, and Patience

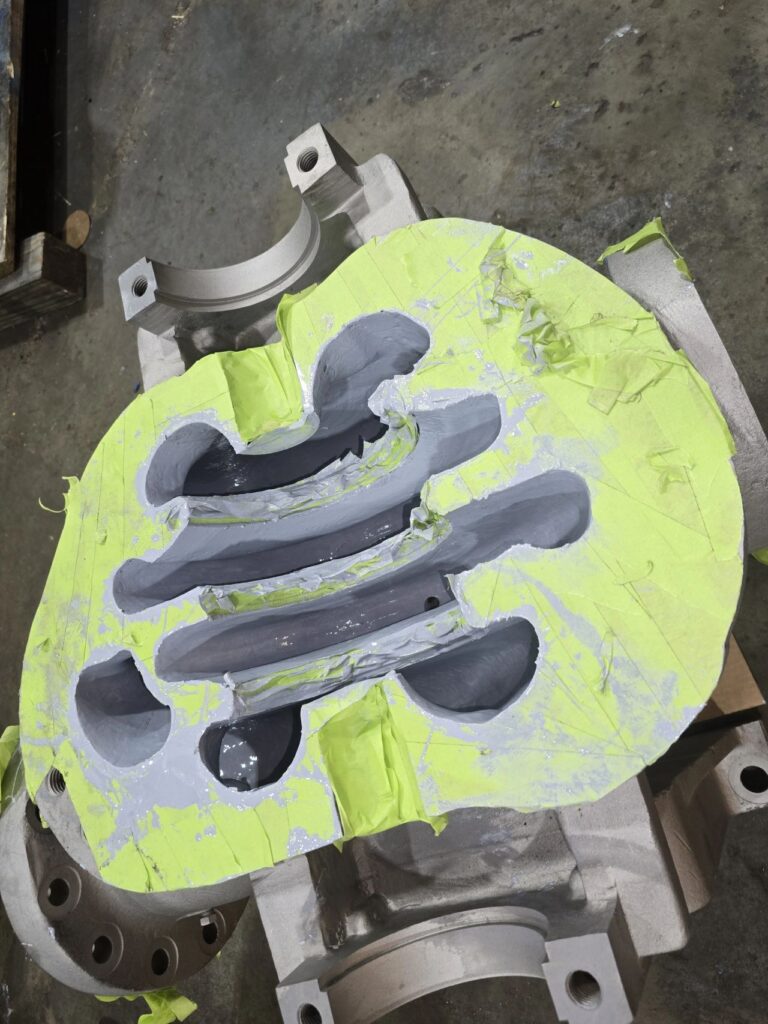

Applying Belzona 1341 requires careful attention to technique and timing. The process typically involves multiple coats, with the second coat applied while the first remains tacky. This timing is crucial for achieving proper adhesion between layers and optimal performance characteristics.

The application process, while straightforward in concept, requires skill and experience to execute properly. As practitioners candidly acknowledge, these repairs are often “not the quickest (or most enjoyable) job, but the right one” to ensure long-term equipment reliability. The time investment in proper application pays dividends in extended service life and improved performance. According to Belzona, proper use of Supermetalglide results in “Efficiency increases of up to 7% have been recorded on new equipment and up to 20% on refurbished equipment.”

When dealing with complex repairs that combine structural restoration with protective coating, the process becomes even more involved. A typical comprehensive repair might involve using Belzona 1111 for structural rebuilding of damaged areas, followed by the application of Belzona 1341 SuperMetalGlide across the entire surface for protection. This multi-step approach requires patience and attention to detail but delivers superior long-term results.

Addressing the Balancing Challenge

One of the most practical considerations when coating impellers is the impact on rotor balance. Adding coating material changes the mass distribution of the impeller, which can affect the dynamic balance of the rotating assembly.

Experienced professionals have developed strategies to manage this challenge effectively. The key is to achieve the tightest possible balance on the initial run, allowing for some tolerance when the second balancing operation is performed after coating application. While this double-balancing requirement adds complexity to the repair process, skilled technicians can minimize the impact through careful planning and execution.

Cost-Benefit Analysis: When Coating Makes Sense

The decision to use Belzona 1341 versus upgrading metallurgy often comes down to practical economics and operational considerations. Coating applications are particularly attractive when:

Replacement costs are high: With extended lead times for new parts becoming increasingly common, coating existing components can provide a faster return to service.

Downtime costs are significant: The ability to restore equipment performance without waiting for new parts can prevent costly production interruptions.

Wear patterns are manageable: For applications where coating can provide adequate protection, it offers a cost-effective alternative to metallurgy upgrades.

However, it’s important to recognize when coating may not be the optimal solution. In cases where frequent repairs indicate that the base material is fundamentally unsuitable for the operating conditions, investigating metallurgy upgrades or design modifications may provide better long-term value.

Looking Forward: Strategic Maintenance Planning

The use of advanced coatings like Belzona 1341 Supermetalglide represents a broader shift toward strategic maintenance planning that emphasizes extending asset life through smart material solutions. As supply chain challenges continue to affect parts availability and costs, these technologies become increasingly valuable tools in the maintenance professional’s toolkit.

However, successful implementation requires understanding both the capabilities and limitations of coating solutions. While Belzona 1341 can provide excellent protection and performance improvements in appropriate applications, it’s not a universal solution for all pump maintenance challenges. If you are ready to discuss whether repair makes sense for your equipment challenges, contact our Service & Repair team: