BALTIMORE, MD – June 16, 2025 – Geiger Pump & Equipment Company, a leading provider of industrial pumping solutions in the Mid-Atlantic region, today announced it has been named an authorized distributor for Gorman-Rupp, an industry-leading manufacturer of high-quality pumps and pumping systems. This strategic partnership expands Geiger’s comprehensive lineup of pumping solutions while providing … Continued

When it comes to pump maintenance and repair, industrial professionals are constantly seeking solutions that balance cost-effectiveness with long-term reliability. One such solution that has proven its worth in the field is Belzona 1341 Supermetalglide, a specialized coating that’s transforming how we approach pumps, pipes, valves and other fluid handling equipment restoration and protection. The … Continued

We’re thrilled to announce that Geiger Pump & Equipment will be exhibiting at the Crane Engineering Tech Expo on May 14th, 2025 in Milwaukee, Wisconsin. Our team is traveling from across the country to attend this important industry event. As proud members of the Crane Group of companies, we’re excited to connect with industry professionals … Continued

Strategic partnership expands Geiger’s comprehensive industrial solutions portfolio with high-quality blower technologies BALTIMORE, MD – April 10, 2025 – Geiger Pump and Equipment, a leading provider of industrial pumping solutions, now represents Continental Blower in the Mid-Atlantic region. This new partnership enables Geiger to offer Continental Blower’s complete range of high-performance blower systems to customers … Continued

A comprehensive failure analysis was conducted on a Goulds 3296 EZMAG magnetic drive pump following operational issues. The investigation was performed by our engineering team. Failure Analysis Findings The inspection revealed several critical issues related to extended dry run operation: Root Cause Of Goulds 3296 EZMAG Failure Based on the physical evidence, it was determined … Continued

You already know that non-OEM parts are typically cheaper, but do they really save you money in the long run? Let’s go over the facts. When maintaining or repairing your Goulds pump, one of the most critical decisions you’ll face is whether to purchase original equipment manufacturer (OEM) parts or opt for non-OEM alternatives. This … Continued

Emergency Goulds 3196 ANSI Pump Stock & Expert Service: How Geiger Restored Plant Operations Same-Day

When the call came in at 7:30 AM, we knew it was serious. One of the region’s busy manufacturing plants had shut down production because their longstanding (and critical) Goulds 3196 ANSI pump was down without backup. They called on Geiger’s technical expertise and on-hand inventory to get them back up and running. A Pump … Continued

Air-operated double diaphragm (AODD) pump failures can lead to significant environmental and financial consequences for manufacturers. When diaphragms rupture, the resulting spills create complex cleanup challenges and substantial costs. Understanding the Cost of Spills Spill cleanup typically involves using absorbent materials like oil-dry or kitty litter, followed by manual removal and disposal. The situation becomes … Continued

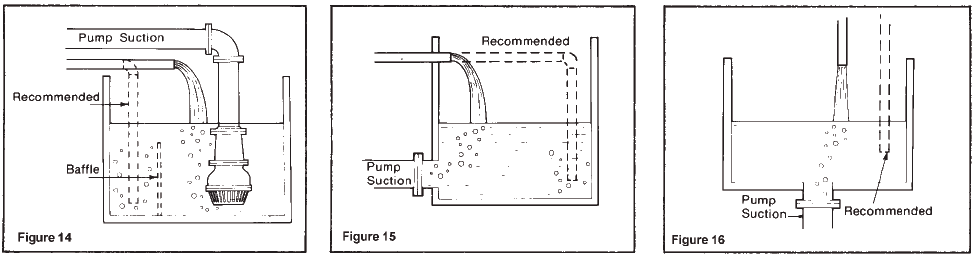

Centrifugal pumps are designed to move fluids, not air. When air becomes entrained in your pump system, it can lead to numerous operational issues and frustrations. If you suspect air might be causing problems in your pump, this guide will help you identify the symptoms and understand the common causes. The Impact of Air Entrainment … Continued

Is your pump making popping sounds or noise that resembles pumping marbles? You might be dealing with cavitation, a serious issue that can lead to increased energy consumption, excessive noise, and severe pump damage. Understanding Pump Cavitation Causes & Effects Cavitation occurs when bubbles form in the liquid around a pump’s impeller due to areas … Continued